- This topic is empty.

-

AuthorPosts

-

29/04/2025 at 17:55 #4712

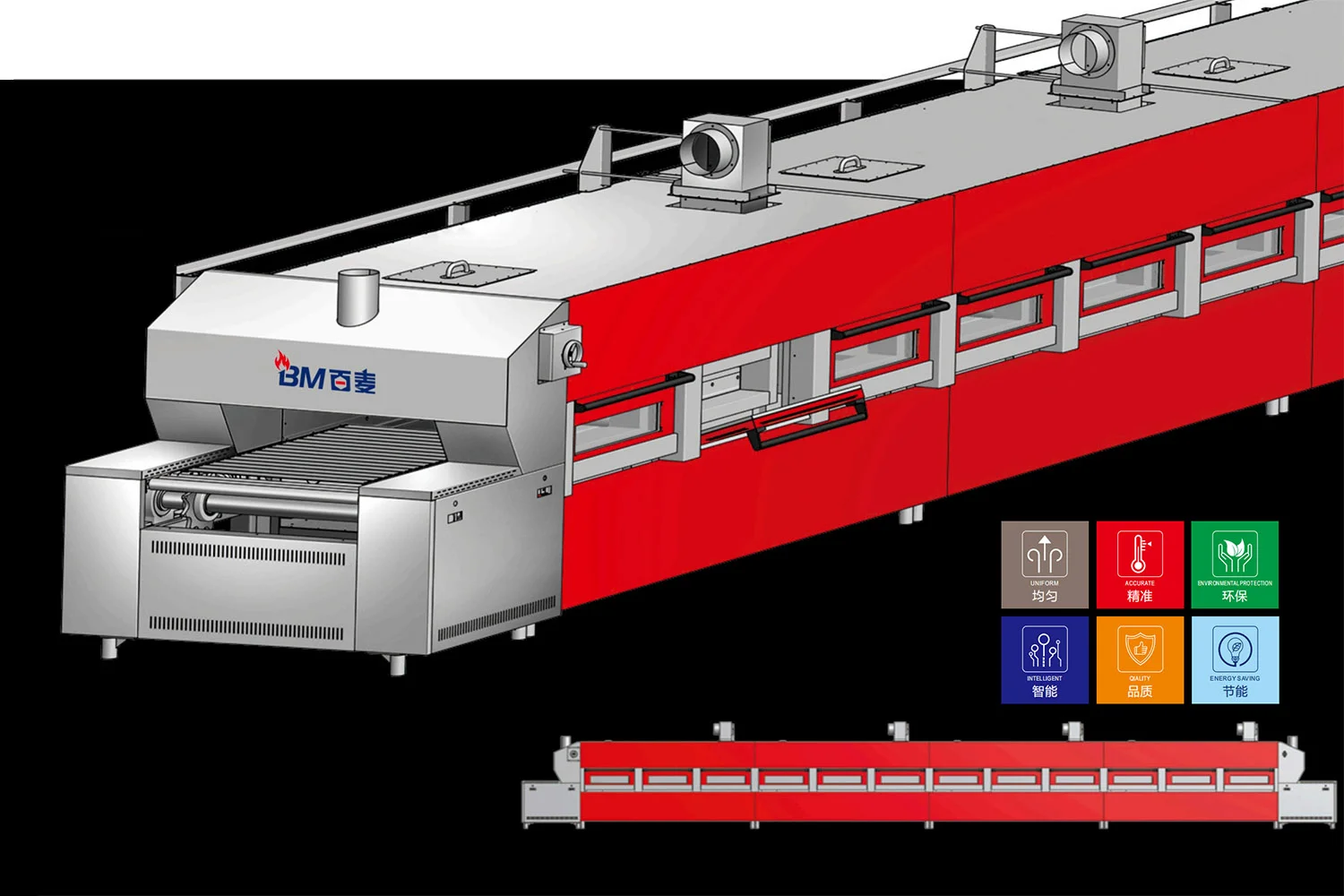

In the ever-evolving world of industrial baking, the need for consistency, scalability, and precision is paramount. Industrial tunnel ovens improve efficiency and quality control in commercial bakeries, providing unparalleled consistency, uniformity, and flexibility in the bread baking process. In this blog post, as a high quality automatic bread production line supplier, Baimai will share the application of precision industrial tunnel oven in bread production, including technical structure, etc.

1. Introduction to Tunnel Ovens in Baking Industry

Tunnel ovens are long, continuous baking systems where the dough products travel through the baking chamber on a conveyor system. These ovens differ from batch ovens in that they are designed for uninterrupted production, making them ideal for large-scale operations. Precision tunnel ovens enhance this model by incorporating advanced thermal control systems, data integration, and zone-specific parameters that enable fine-tuned baking profiles tailored to specific bread types.

2. Technical Structure of Industrial Tunnel Oven

A precision industrial tunnel oven is a sophisticated assembly comprising multiple integrated components:

a. Conveyor System

The conveyor is the backbone of the tunnel oven. It may consist of mesh belts, stone hearths, or steel bands, depending on the type of bread and desired crust characteristics. Conveyor speed is adjustable and typically integrated with PLCs (Programmable Logic Controllers) to synchronize with upstream and downstream processes.

b. Zoned Heating Chambers

Tunnel ovens are divided into multiple heating zones, each with independently controlled heat sources. Zones may be configured for:

– Radiant heat

– Convection (hot air)

– Conduction (via the oven floor)

– Hybrid combinations for optimized baking

This zoning enables the customization of thermal profiles to accommodate the unique baking curves of different bread types—artisan loaves, sandwich bread, or baguettes.

c. Burner and Heat Source Configurations

Heat sources include gas burners (direct or indirect-fired), electric coils, or infrared elements. Advanced systems can modulate burner intensity in real-time, ensuring even heat distribution and temperature consistency throughout the baking chamber.

d. Airflow and Steam Injection Systems

Uniform airflow is critical for consistent crust formation and crumb texture. Fans and ducts are designed to circulate hot air efficiently. Steam injection systems introduce controlled bursts of moisture, which are crucial in developing glossy, crack-resistant crusts in products like ciabatta or Vienna rolls.

3. Integration into Bread Production Lines

Precision tunnel ovens are typically integrated into fully automated bread lines, which may include:

– Dough mixing and bulk fermentation

– Dividing and moulding stations

– Proofing chambers

– Panning and depanning systems

– Post-bake cooling tunnels

This seamless integration reduces manual handling, minimizes contamination risks, and ensures consistent product quality across multiple shifts and batches.

4. Precision Baking and Thermal Profiling

The success of bread baking lies in accurately managing the thermal profile throughout the baking process. A precision tunnel oven enables exact control of three primary baking phases:

a. Oven Spring (Expansion Phase)

During the first few minutes, steam injection and high humidity zones promote optimal oven spring by delaying crust formation and allowing gases to expand the dough matrix. Zone temperatures are typically set 20–30°C above the target internal bread temperature to drive initial rise.

b. Starch Gelatinization and Protein Coagulation

Mid-zone temperatures are regulated to trigger starch gelatinization (60–70°C) and gluten protein coagulation (70–80°C). Controlled airflow prevents crust cracking and ensures uniform crumb structure.

c. Crust Formation and Caramelization

The final zones employ dry heat and reduced humidity to drive off moisture, promote Maillard reactions, and form a desirable crust. These zones may incorporate radiant heaters or ceramic elements to provide finishing touches in terms of crust color and crispness.

Precision in each of these stages ensures the final bread meets desired specifications for volume, texture, moisture content, and crust quality.

5. Advantages of Using Industrial Tunnel Oven

a. Consistency and Repeatability

Precision tunnel ovens allow bakers to replicate exact baking conditions over long runs. This is crucial for brand consistency, especially in commercial baking where uniformity is key.

b. Increased Throughput

With continuous operation and high-speed conveyors, tunnel ovens significantly increase production capacity. A single oven can bake tens of thousands of loaves daily, making it suitable for national and international supply chains.

c. Energy Efficiency

Modern tunnel ovens utilize thermal insulation, waste heat recovery, and intelligent control systems to minimize energy consumption. Precise zoning ensures that only required sections are heated, avoiding energy wastage.

d. Scalability and Flexibility

Despite being large systems, precision tunnel ovens can be designed for modular expansion or to handle different product SKUs via adjustable bake profiles. Quick changeover systems and recipe memory functions enhance product line flexibility.

e. Hygiene and Cleanability

Hygienic design principles, including stainless steel interiors, accessible belt cleaning systems, and CIP (Clean-in-Place) capability, ensure compliance with food safety standards and reduce downtime during cleaning.

6. Applications of Industrial Tunnel Oven in Bread Products

a. Artisan Breads

For artisan-style breads requiring long fermentation and specific crust characteristics, tunnel ovens with stone hearths and steam systems replicate traditional baking environments at scale.

b. Sandwich and Pan Breads

Soft, uniform-texture loaves benefit from ovens with indirect-fired convection zones and precise pan tracking systems. These ovens are often integrated with depanners and slicers for post-bake processing.

c. Flatbreads and Tortillas

High-temperature, short-time baking is needed for flatbreads. Precision tunnel ovens with infrared zones or flame burners can quickly bake and blister the surface while maintaining softness.

d. Gluten-Free Breads

Delicate gluten-free formulations require gentle and even heat. Tunnel ovens with integrated moisture control and lower radiant heat intensity can handle such products without compromising texture.

7. Maintenance and Operational Considerations

While tunnel ovens are robust, regular maintenance is essential to prevent performance degradation:

– Calibration of sensors (temperature, humidity, belt speed)

– Routine inspection of burners, fans, and belts

– Software updates for control systems and diagnostics

– Spare parts management for motors, belts, and thermocouples

Downtime costs in continuous baking environments can be high, so many bakeries opt for remote monitoring and predictive maintenance via IoT-enabled systems.

Conclusion

Precision industrial tunnel ovens have become an indispensable asset in modern bread production. By combining advanced thermal engineering with digital control systems, they offer unmatched consistency, efficiency, and flexibility. Whether for mass-market pan bread or artisanal loaves, tunnel ovens empower bakeries to scale production without compromising on quality. As baking technologies continue to evolve, tunnel ovens will remain at the heart of innovation, driving the industry toward greater precision, automation, and sustainability.

http://www.bmbaking.com

Baimai -

AuthorPosts

- You must be logged in to reply to this topic.