- This topic is empty.

-

AuthorPosts

-

01/04/2025 at 18:24 #4490

In healthcare environments, maintaining optimal air quality and circulation isn't just a comfort—it's a necessity. Proper ventilation prevents airborne diseases, minimizes infection risks, enhances patient safety, and ensures healthcare providers can perform their duties effectively. Within these settings, specialized ventilation equipment plays an integral role, with plastic centrifugal fans increasingly recognized for their reliability, efficiency, and hygiene-related benefits.

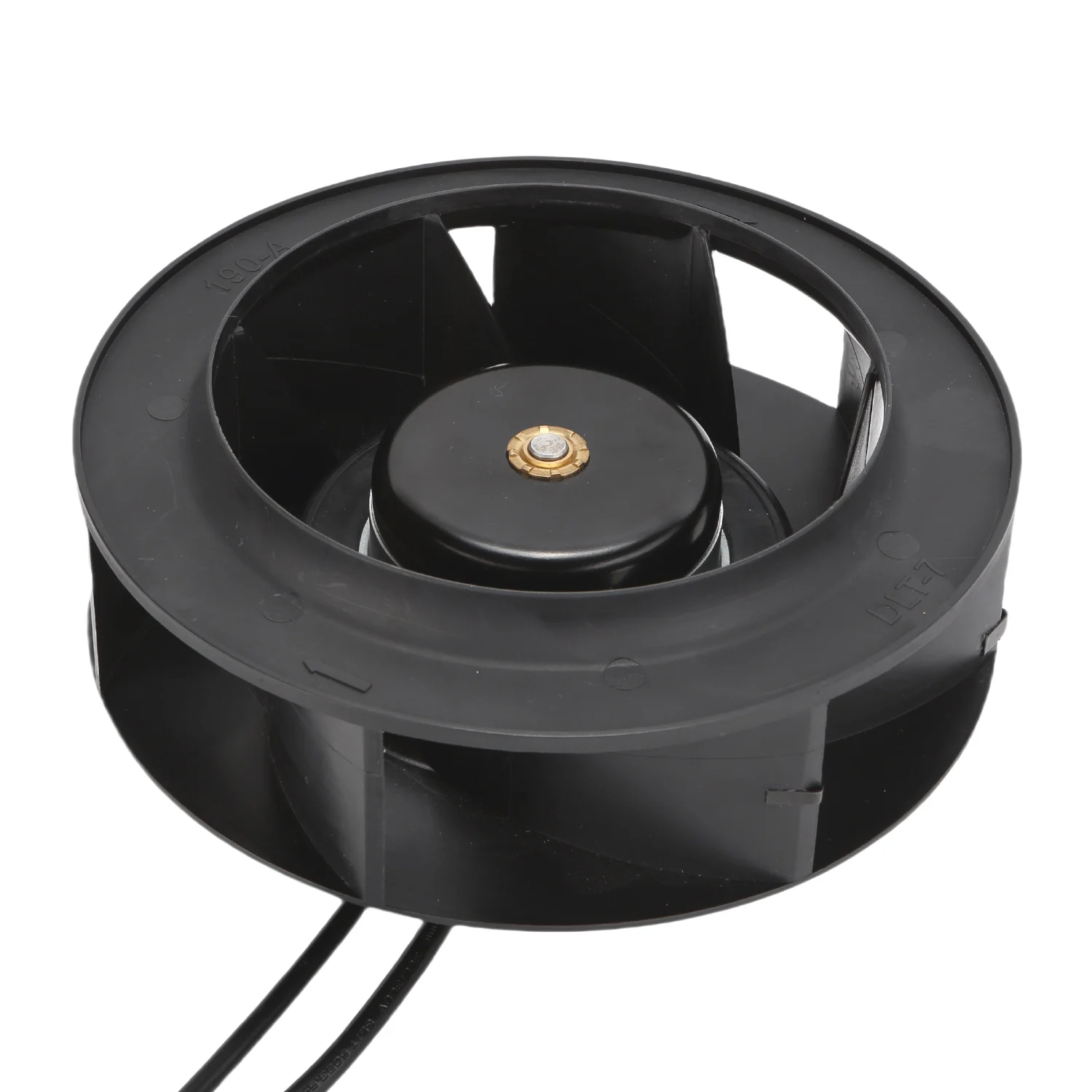

Plastic centrifugal fans, engineered specifically for healthcare applications, offer robust solutions to air circulation challenges faced by hospitals, laboratories, cleanrooms, medical device manufacturing, pharmaceutical facilities, and isolation units. Made from high-quality plastics, these fans are resistant to corrosion, contamination, and chemical interactions. Their superior material properties ensure optimal performance in controlled, sensitive environments typical in the medical industry.

Why Plastic Centrifugal Fan is Essential in Medical Setting

1. Superior Chemical and Corrosion Resistance for Hygienic Environments

Medical environments frequently employ strong disinfectants, sterilizing agents, and chemical cleaners to maintain sanitary conditions. Traditional metallic ventilation components may suffer rapid corrosion when exposed to these harsh substances. In contrast, plastic centrifugal fans are manufactured from chemically inert polymers such as polypropylene, polycarbonate, or reinforced plastics. These materials inherently resist corrosion, chemical attacks, and moisture-induced deterioration, providing consistent performance without compromising structural integrity or air quality.

By selecting plastic centrifugal fans, hospitals and medical facilities ensure long-lasting durability and hygiene. These fans do not degrade, rust, or shed particulate matter, thus protecting sensitive medical equipment and sterile environments from contamination. This chemical resistance also minimizes ongoing maintenance costs, reducing downtime and providing greater long-term cost-efficiency compared to traditional metal-based systems.

2. Lightweight Construction and Easy Integration into Medical Equipment

Another distinct advantage of using plastic centrifugal fans within medical environments is their lightweight nature. Unlike metal fans, plastic alternatives are significantly lighter, enabling more flexible installation options, reduced structural demands, and easier integration into medical ventilation systems and equipment. This lightweight characteristic is particularly beneficial when embedding ventilation components into compact or portable medical devices—such as patient ventilators, respiratory therapy units, sterilization chambers, laboratory fume hoods, and mobile isolation units. Moreover, lightweight plastic centrifugal fans help reduce the overall energy consumption of ventilation systems. With lower mass to rotate, these fans require less mechanical energy to operate, providing substantial energy savings and helping healthcare facilities meet increasingly stringent energy efficiency targets and sustainability goals.

3. Enhanced Noise Reduction for Improved Patient Comfort

Noise management is a critical concern in medical facilities. Excessive noise contributes significantly to patient anxiety, stress, sleep disruption, and discomfort. Plastic centrifugal fans provide substantial acoustic advantages compared to traditional metal-based counterparts. The inherent damping properties of plastic materials significantly reduce vibration and operational noise. This ensures quieter airflow performance, directly enhancing patient comfort and staff concentration. Especially in areas such as intensive care units (ICUs), neonatal care wards, surgical theaters, and patient recovery rooms, quiet operation is crucial. Plastic centrifugal fans contribute significantly to creating calm, peaceful environments, promoting faster patient recovery and enhancing the overall patient experience.

4. Hygienic Design and Reduced Risk of Contamination

The smooth, non-porous surfaces typical of plastic centrifugal fans facilitate hygienic operation and easy cleaning, greatly reducing contamination risks. Their surfaces discourage microbial growth, mold formation, and accumulation of airborne particulates—factors critical in infection-sensitive medical areas like operating theaters, isolation rooms, laboratories, and pharmaceutical manufacturing zones. Additionally, plastic centrifugal fans can easily withstand aggressive sterilization procedures without degradation, maintaining their structural and operational integrity throughout their lifecycle. This ease of cleaning and resistance to microbial contamination makes these fans ideal for rigorous hygiene standards required in modern medical settings.

Key Applications of Plastic Centrifugal Fans in Healthcare Facilities

1. Isolation Wards and Infection Control Units

Effective ventilation in isolation wards is essential to control airborne infections and protect healthcare professionals and other patients. Plastic centrifugal fans are specifically engineered to support negative-pressure rooms, preventing potentially contaminated air from escaping to other facility areas. Their robust construction and chemical-resistant properties ensure long-term reliable operation even under demanding sterilization conditions and continuous use. Moreover, plastic centrifugal fans assist in removing airborne pathogens efficiently, ensuring clean air circulation, reducing transmission risk, and promoting overall facility safety.

2. Laboratory Fume Extraction and Pharmaceutical Cleanrooms

Laboratories and pharmaceutical cleanrooms demand stringent ventilation and air filtration standards to prevent contamination of sensitive experiments, research, and manufacturing processes. Plastic centrifugal fans play a pivotal role here, efficiently extracting hazardous chemical fumes, vapors, particulates, and volatile organic compounds (VOCs), thereby maintaining strict air purity and safety standards. These fans integrate seamlessly with filtration and scrubber systems, delivering continuous, chemically resistant airflow. Their corrosion-resistant plastic construction ensures longevity and consistent performance, even when exposed daily to aggressive chemical fumes common in laboratory environments.

3. Surgical and Sterilization Environments

Operating theaters and sterilization facilities require precise airflow management to maintain sterility, prevent infections, and ensure optimal surgical outcomes. Plastic centrifugal fans are ideally suited for these environments, providing consistent air exchange rates, quiet operation, and minimal vibration—critical factors contributing to surgical precision and patient safety. The smooth surfaces of plastic fans also significantly minimize potential contaminants, support rigorous sterilization processes, and meet demanding hygiene standards that surgical and sterilization zones require.

4. Ventilation in Diagnostic and Imaging Equipment

Plastic centrifugal fans also play a critical role in medical imaging and diagnostic equipment, including MRI, CT, and X-ray machines. These systems often require cooling and internal air circulation to ensure safe, reliable operation. Plastic centrifugal fans deliver precise and efficient airflow within these enclosed, sophisticated devices, protecting sensitive electronic components from overheating or damage, thereby ensuring consistent diagnostic accuracy. The non-metallic nature of plastic fans is also ideal for equipment sensitive to electromagnetic interference, reducing the potential for imaging distortions or inaccuracies in patient diagnosis.

In the healthcare industry, effective air management directly impacts patient safety, recovery outcomes, and staff efficiency. The adoption of plastic centrifugal fans in hospitals, laboratories, pharmaceutical plants, and medical equipment manufacturing has become increasingly prevalent due to their remarkable chemical resistance, hygienic properties, quiet performance, lightweight construction, and cost-effectiveness.

Healthcare facilities that prioritize using high-quality plastic centrifugal fans ensure superior indoor air quality, robust protection against contamination, and improved patient and staff comfort—ultimately resulting in better healthcare outcomes, reduced operational costs, and enhanced facility sustainability. As healthcare ventilation standards evolve, plastic centrifugal fans clearly emerge as the best-performing, safest, and most hygienic solution to meet these stringent demands.

https://www.szcaforre.com/Plastic-Centrifugal-Fan-Ensuring-Optimal-Air-Quality-in-Healthcare.html

https://www.szcaforre.com/DC9225-Centrifugal-Cooling-Fan.html

http://www.szcaforre.com

Shenzhen Caforre Technology Co.,Ltd. -

AuthorPosts

- You must be logged in to reply to this topic.