- This topic is empty.

-

AuthorPosts

-

25/04/2025 at 17:59 #4673

In the realm of high-performance machinery, every component plays a crucial role in ensuring optimal performance, efficiency, and durability. One such critical component is the precision milled pressure plate. These plates are integral to various industrial applications, from automotive clutches to heavy-duty manufacturing equipment. This article delves into the importance of precision milled pressure plates, their manufacturing process, and their impact on high-performance machinery.

Understanding Precision Milled Pressure Plates

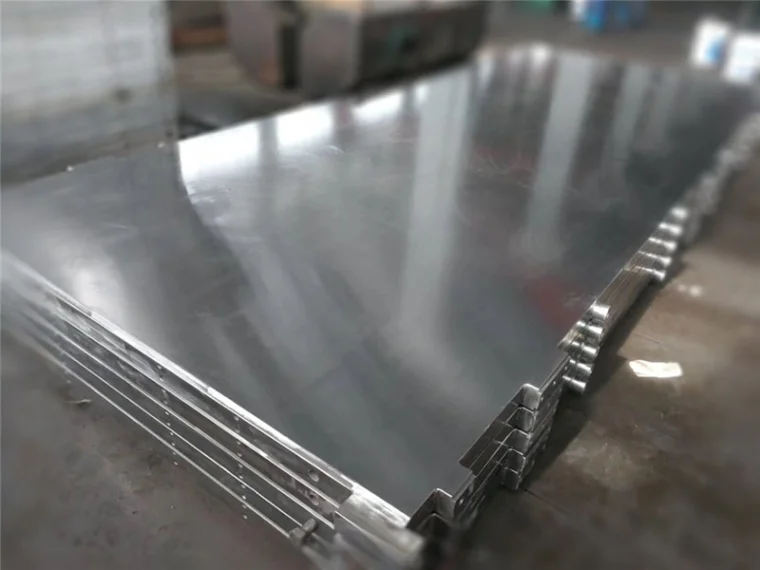

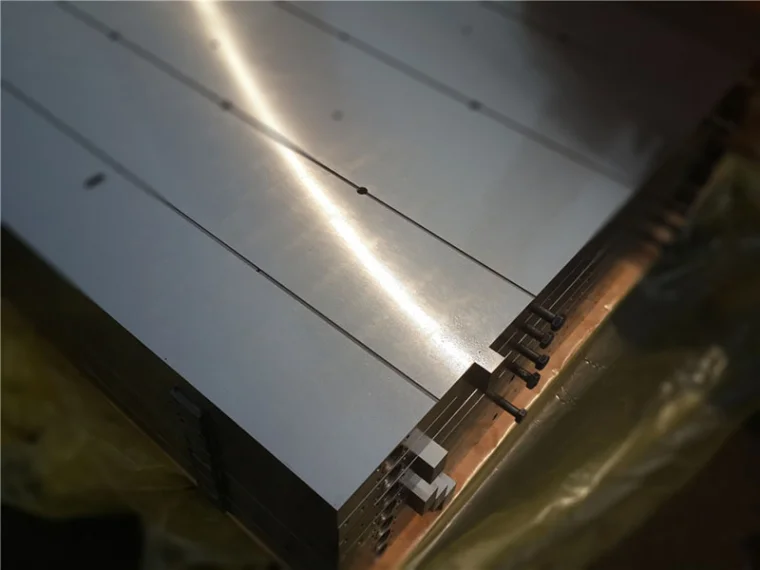

A pressure plate is a component commonly found in mechanical systems that require precise force application, such as clutches and brake assemblies. The term "precision milled" refers to the high-accuracy machining process used to manufacture these plates, ensuring uniformity, smooth surface finish, and tight tolerances.

Precision milled pressure plates are widely used in:

-

Automotive Clutch Systems – They provide the necessary force to engage and disengage the clutch smoothly.

-

Aerospace Applications – Used in high-stress environments where precision and reliability are paramount.

-

Industrial Machinery – Critical in presses, stamping machines, and other high-load applications.

-

Renewable Energy Systems – Essential for wind turbines and other power generation equipment.

The Manufacturing Process of Precision Milled Pressure Plates

The production of precision milled pressure plates involves multiple stages to ensure superior quality and performance. The key steps include:

1. Material Selection

The first step in manufacturing pressure plates is choosing the right material. Common materials include:

-

Hardened Steel – Offers durability and high resistance to wear.

-

Aluminum Alloys – Lightweight and corrosion-resistant, ideal for aerospace applications.

-

Cast Iron – Provides excellent heat dissipation, making it suitable for high-friction applications.

2. CNC Milling and Machining

Computer Numerical Control (CNC) milling is the primary method used to create precision pressure plates. The benefits of CNC milling include:

-

High accuracy and repeatability.

-

Ability to produce complex geometries.

-

Enhanced surface finish and dimensional stability.

3. Heat Treatment and Surface Finishing

To enhance durability, pressure plates undergo heat treatment processes such as:

-

Quenching and Tempering – Improves toughness and strength.

-

Nitriding – Increases surface hardness and wear resistance.

Additionally, coatings like ceramic or friction-resistant materials may be applied to improve performance.

Key Benefits of Precision Milled Pressure Plates

Precision milled pressure plates offer numerous advantages over conventional alternatives. These include:

1. Enhanced Performance and Efficiency

Precision machining ensures that pressure plates maintain consistent thickness and surface uniformity. This minimizes vibrations and enhances the efficiency of mechanical systems.

2. Increased Durability and Wear Resistance

By using high-quality materials and advanced heat treatment processes, precision milled pressure plates exhibit superior resistance to wear and tear, making them ideal for high-load applications.

3. Improved Heat Dissipation

In applications such as automotive clutches and industrial brakes, heat generation is a major concern. Precision milled plates are designed to dissipate heat effectively, preventing overheating and ensuring long-term functionality.

4. Reduced Maintenance Costs

High-quality pressure plates require less frequent replacement and maintenance, leading to lower operational costs and improved system reliability.

Applications of Precision Milled Pressure Plates in High-Performance Machinery

1. Automotive Industry

In high-performance vehicles, clutch systems rely on precision milled pressure plates to provide smooth engagement and disengagement. These plates must withstand high rotational speeds and extreme pressure.

2. Aerospace and Aviation

Aircraft systems demand components with exceptional precision and durability. Pressure plates used in aerospace applications must endure high stress, temperature variations, and rigorous operational conditions.

3. Industrial Manufacturing Equipment

In manufacturing, precision milled pressure plates are essential in stamping presses, injection molding machines, and heavy-duty hydraulic systems. Their role is to ensure precise force application and maintain the integrity of the manufacturing process.

4. Renewable Energy Systems

Wind turbines and hydroelectric plants use pressure plates to regulate force distribution and mechanical engagement. Their precision machining ensures smooth operation, reducing energy loss and increasing efficiency.

Conclusion

Precision milled pressure plates are indispensable components in high-performance machinery. Their role in enhancing efficiency, durability, and heat management makes them a critical investment for industries requiring high precision and reliability. As technology continues to evolve, the performance of pressure plates will only improve, driving advancements across various industrial sectors.

Whether in automotive, aerospace, or industrial applications, the demand for high-quality precision milled pressure plates remains strong. By leveraging advanced manufacturing techniques, businesses can achieve superior mechanical performance and longevity in their high-performance machinery.

Precision Milled Pressure Plate: Custom Solutions for Your Manufacturing Needs

http://www.nuknail.com

Kunshan Liankun Hotplaten Co., Ltd. -

-

AuthorPosts

- You must be logged in to reply to this topic.